| Today |

| Carolyn's World |

| Gear & Gadgets |

| Garage |

| Garden |

| Kitchen |

| Unaccompanied Minors |

| Workshops |

| Contact Us |

| Index |

RainyDayRenovations...

|

||

|

The BionicGrip's construction is very similar to the BionicWrench. Both units are based on Loggerhead Tool's patented grip design which prevents stripping of the nut. The BionicGrip's open throat also allows the tool to grip items such as tubes and pipes.

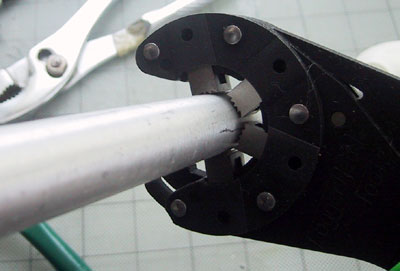

The lever action is similar to the BionicWrench. Squeezing the grip will apply even pressure from the four serated jaw blocks.

The BionicGrip's, like the BionicWrench, is made using multiple layers of steel. We like this approach as it usually provides superior structural strength compared to casting or milling. For an improved grip on round surfaces, the BionicGrip has serated teeth on the four grip blocks. This is a necessary addition for the tool, but it may mar the surface of the item. We feel that it was a worthwhile functional tradeoff. How will the traditional tools compare to the BionicGrip? We rounded up three representative tools (adjustible wrench, pliers, pipe wrench) to go head-to-head with the BionicGrip.

As can be seen in these photos, the surface contact of the traditional tools are less compared to the BionicGrip. The larger surface contact of the BionicGrip translates directly to more torque applied to the turning or force in the grip.

In using the BionicWrench these past months, we have found it to be quite versatile. We have also noticed a few situations where both tools cannot replace the traditional tool. The main issue is, unlike the traditional pliers, neither device can close its grip on a thin piece of material. The BionicWrench or the BionicGrip is still the first tool we reach for, it it works for the job, we use it...if not, then we look for something else.

|

LoggerHead Tools Bionic Grip |

|

When we first reported on the BionicWrench, we did a detailed review comparing it to standard wrenches and pliers. The same analysis holds for the BionicGrip.

The obvious difference is that LoggerHead Tools has addressed our one issue with the original BionicWrench...its inability to grip pipes due to its closed loop design.

Squeezing the handle of the BionicGrip will cause the teeth to exert even pressure on the object. Unlike the BionicWrench, the teeth on the BionicGrip are serrated to better hold onto things like tubes and pipes. The BionicGrip will be shipping in July. We have only had the BionicGrip for two days and we already know it'll have a permanent place in our tool box. Review Summary: Initial Impression- Excellent Usability- Open design Durability- Guaranteed For Life Price- $33

|

||